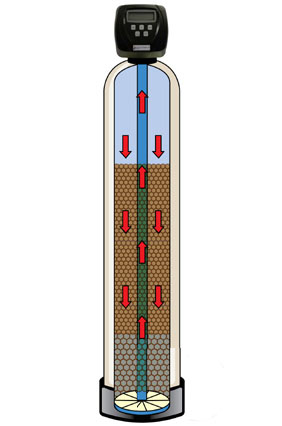

Automatic aeration water deferrization filters remove iron divalent, hydrogen sulphide, magnesium and mechanical impurities from the water. This is due to the aeration principle.

The air compressor provides oxygen to the water. Oxidized divalent iron enters the oxidizing tank, where it is transformed into trivalent iron (rust): Fe² → Fe³. Then the water with mechanical impurities passes through the filtering filler inside the filter housing, where mechanical impurities are trapped. During the rinsing process, the filler is rinsed with water and the collected insoluble particles are rinsed into the drain.

Water deferrization filters also remove hydrogen sulfide, which is removed through the air outlet. Further the water cleared of iron arrives in filters of softening of water. Thus the treated water can be used for domestic and technological needs.

Iron removal filters AFT are a reliable, economical and effective way to remove iron and manganese from well water. The system consists of two filtering strings, an automatic air valve and an electronic control valve. AFT-5010 systems are equipped with an air injector. This is an original technology that provides efficient and accurate air supply to the system.

Operation principle

Water-oxidized filters consist of three parts: an air supply system, an oxidizing tank and a deferrization filter. The filters operate on the principle of aeration, when air is supplied by a compressor or air pump, which is mixed with water in the oxidizing tank. The iron in the water is oxidized and converted to rust. From the oxidizing tank, the water enters the deferrization filter, in which the iron is retained in the filler. The collected iron is removed to the sewerage system during rinsing in accordance with the set program. It is important that there should be a sewerage system and an electric installation port (220V) near the filter installation site.

Water-oxidized filters consist of three parts: an air supply system, an oxidizing tank and a deferrization filter. The filters operate on the principle of aeration, when air is supplied by a compressor or air pump, which is mixed with water in the oxidizing tank. The iron in the water is oxidized and converted to rust. From the oxidizing tank, the water enters the deferrization filter, in which the iron is retained in the filler. The collected iron is removed to the sewerage system during rinsing in accordance with the set program. It is important that there should be a sewerage system and an electric installation port (220V) near the filter installation site.

It is important that this type of filter does not use potassium permanganate or other chemicals that may affect the microbiological wastewater treatment system, if used.

In water, dissolved iron compounds are oxidised and precipitated.

Iron is removed according to this chemical reaction: 4Fe2+ + O2 + 8OH- + 2H2O(FeOH)3→ 4Fe(OH)3↓ . This reaction is accelerated by the produced Fe(OH)3. This oxidation reaction is carried out in the filter AFFO-5010 in the first column. In the second column, the oxidized iron deposits are mechanically filtered with a filter filler. After a certain amount of water has passed through, the filter is periodically washed out and the accumulated sludge is washed off into the sewerage system. To make the process of oxidation and filtration more efficient, forced proportional ventilation is used. AFFO-5010 is an excellent technology for removing iron, sulphur and manganese compounds.

Advantages of AFT filters:

- Proportional input of oxygen (air) into the flowing water;

- Direct water flow;

- More oxidation area - more efficient oxidation;

- Qualitative filtering filler, which also holds fine particles;

- Insignificant amount of water for washing, longer cycle between regenerations;

- Original disassembled joints - easy installation and operation;

- High efficiency at removal of iron, hydrogen sulfide and manganese;

- Clean and delicious water from your well;

- Ceramics of a bathroom and the equipment - pure, without iron precipitation;

- From a rust protected home appliances;

- The filter is suitable for local purification facilities.

|

|

Max. water pressure, bar |

Temperature range, °C |

Filling volume, l |

Filter column size |

Nominal / Maximum capacity, m3/h |

Control valve capacity, W |

Connection diameter, inches |

Filter system size (L x H x W), cm |

|

AFT-5008 |

8,0 |

from -4 to +38 |

25 |

8x44 2 vnt. |

|

5 |

1 |

132 x 56 x 23 |

|

AFT-5008-2 |

8,0 |

from -4 to+38 |

25 |

10 x 35 2 vnt. |

0,6 / 0,8 |

5 |

1 |

|

|

AFT-5009 |

8,0 |

from -4 to +38 |

32 |

10 x 44 2 vnt. |

|

5 |

1 |

130x70x25 |

|

AFT-5010 |

8,0 |

from -4 to+38 |

35,37 |

2 vnt. |

1,0 / 1,6 |

5 |

1 |

160 x70x25 |

|

AFT-5012 |

8,0 |

from -4 to +38 |

60 |

12 x 52 2 vnt. |

1,5 / 2,2 |

5 |

1 |

155x80x30 |

|

AFT-7713 |

8,0 |

from -4 to +38 |

70 |

13 x 54 2 vnt. |

|

5 |

1 |

160x33x33 |

Automatic aeration deferrization filters with air injector and oxidizing tank

|

|

Filler volume, l |

Filter column size |

Nominal / Maximum capacity, m3/h |

Connection diameter, inches |

Filter system size (L x H x W), cm |

|

AFT-50-8MXO |

22 |

08x44 |

0,5/0,8 |

1 |

600 x 1300 x 250 |

|

AFT-50-9MXO |

32 |

10x44 |

0,6/1,0 |

1 |

700 x 1300 x 250 |

|

AFT-50-10MXO |

42 |

10x54 |

0,8/1,3 |

1 |

700 x 1600 x 250 |

|

AFT-50-12MXO |

60 |

12x52 |

1,1/1,8 |

1 |

800 x 1550 x 300 |

|

AFT-50-13MXO |

70 |

13x54 |

1,3/2,0 |

1 |

800 x 1600 x 330 |

|

AFT-50-14MXO |

100 |

14x65 |

1,5/2,5 |

1 |

920 x 1850 x 360 |

|

AFT-50-16MXC |

120 |

16x65 |

2,0/3,2 |

1 |

1000 x 1850 x 400 |

|

AFT-27-18MXC |

170 |

18x65 |

2,5/4,0 |

1 |

1220 x 1850 x 460 |

|

AFT-27-21MXC |

200 |

21x60 |

3,4/5,5 |

1 |

1380 x 1530 x 540 |

|

|

Case volume, l |

Filter case size (DxH), inches |

Nominal capacity, m3/h |

Maximum capacity, m3/h |

Connection diameter, inches |

Dimensions of the filtering system (L x H x W), cm |

|

OK-30 |

30 |

08x44 |

0,4 |

4,0 |

1 |

200 x 1300 x 250 |

|

OK-50 |

50 |

10x44 |

0,6 |

4,0 |

1 |

250 x 1300 x 250 |

|

OK-60 |

60 |

10x54 |

0,7 |

4,0 |

1 |

250 x 1600 x 250 |

|

OK-80 |

80 |

12x52 |

1,0 |

4,0 |

1 |

300 x 1550 x 300 |

|

OK-100 |

100 |

13x54 |

1,2 |

4,0 |

1 |

330 x 1600 x 330 |

|

OK-140 |

140 |

14x65 |

1,7 |

12,0 |

1,5 |

360 x 1850 x 360 |

|

OK-170 |

170 |

16x65 |

2,0 |

12,0 |

1,5 |

400 x 1850 x 400 |

|

OK-250 |

250 |

18x65 |

3,0 |

12,0 |

1,5 |

460 x 1850 x 460 |

|

OK-300 |

300 |

21x60 |

3,6 |

12,0 |

1,5 |

540 x 1730 x 540 |

|

OK-500 |

500 |

2 vnt.18x65 |

6,0 |

24,0 |

2x1,5 |

1200 x 1850 x 460 |

|

Ok-600 |

600 |

2 vnt.21x60 |

7,2 |

24,0 |

2x1,5 |

1300 x 1730 x 540 |