ŠOMIS is a supplier of a unique product Siliphos®, created by the specialists of the Japanese company Kurita and designed to stabilize water hardness. Siliphos® is an economical and reliable water treatment system for drinking water and industrial needs.

ŠOMIS is a supplier of a unique product Siliphos®, created by the specialists of the Japanese company Kurita and designed to stabilize water hardness. Siliphos® is an economical and reliable water treatment system for drinking water and industrial needs.

Siliphos® is a calcium polyphosphate, which is made up of well-balanced silicates and inorganic phosphates. Using 1 kg of this product, up to 250 m3 of water can be treated. The product is easy to use. A slowly dissolving Siliphos® reagent feeder is installed on the line between the main pump and the storage tank. Flowing water dissolves the precisely defined amount of Siliphos® , thus preventing scale and corrosion processe.

Siliphos® granules are available in various sizes depending on the dosing system used.

Siliphos® is completely made up of active ingredients, which proves that it is environmentally friendly. The dispenser produces a negligible amount of product. The quality of Siliphos® meets the international standards ISO 9001, NSF, FAO/WHO and FDA. The National Hygiene and Nutrition Centre permits the use of Siliphos® for the treatment of drinking and domestic water (Resolution No. 1205 KČ).

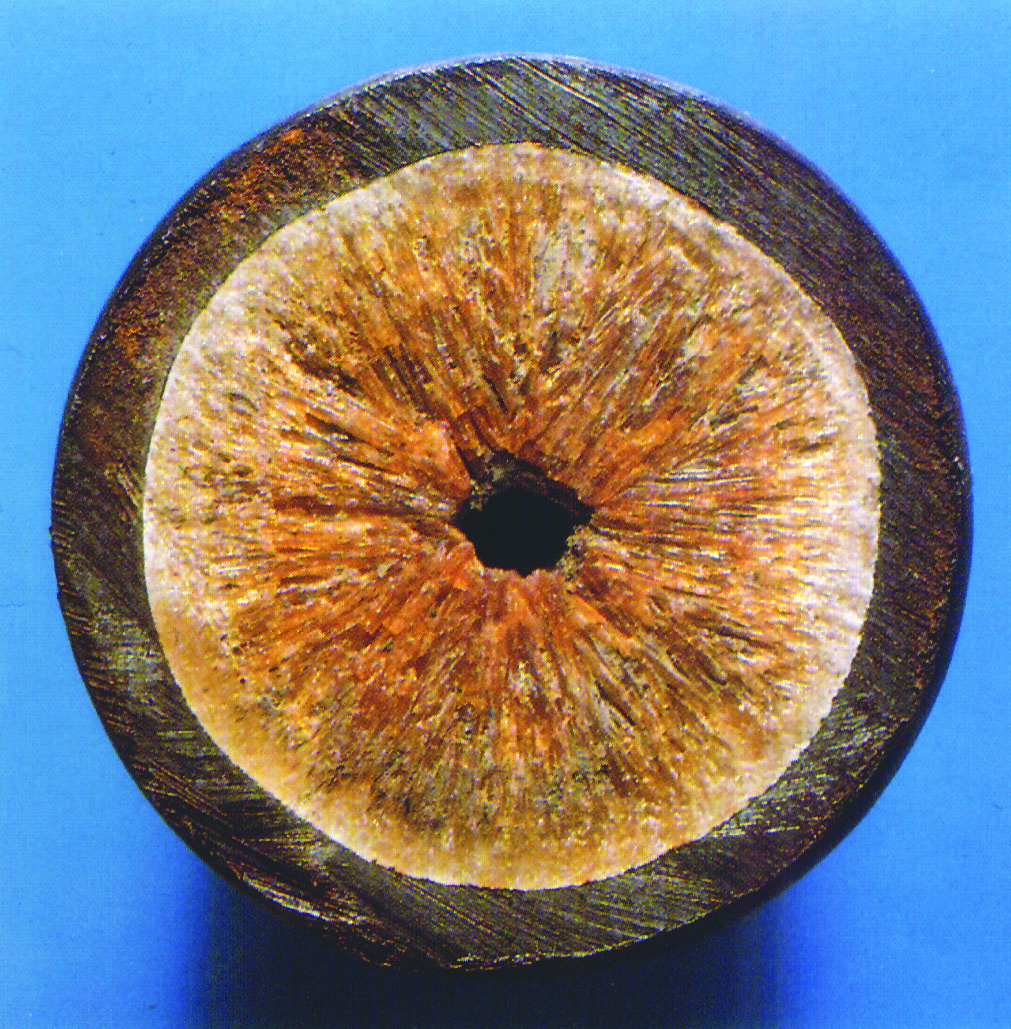

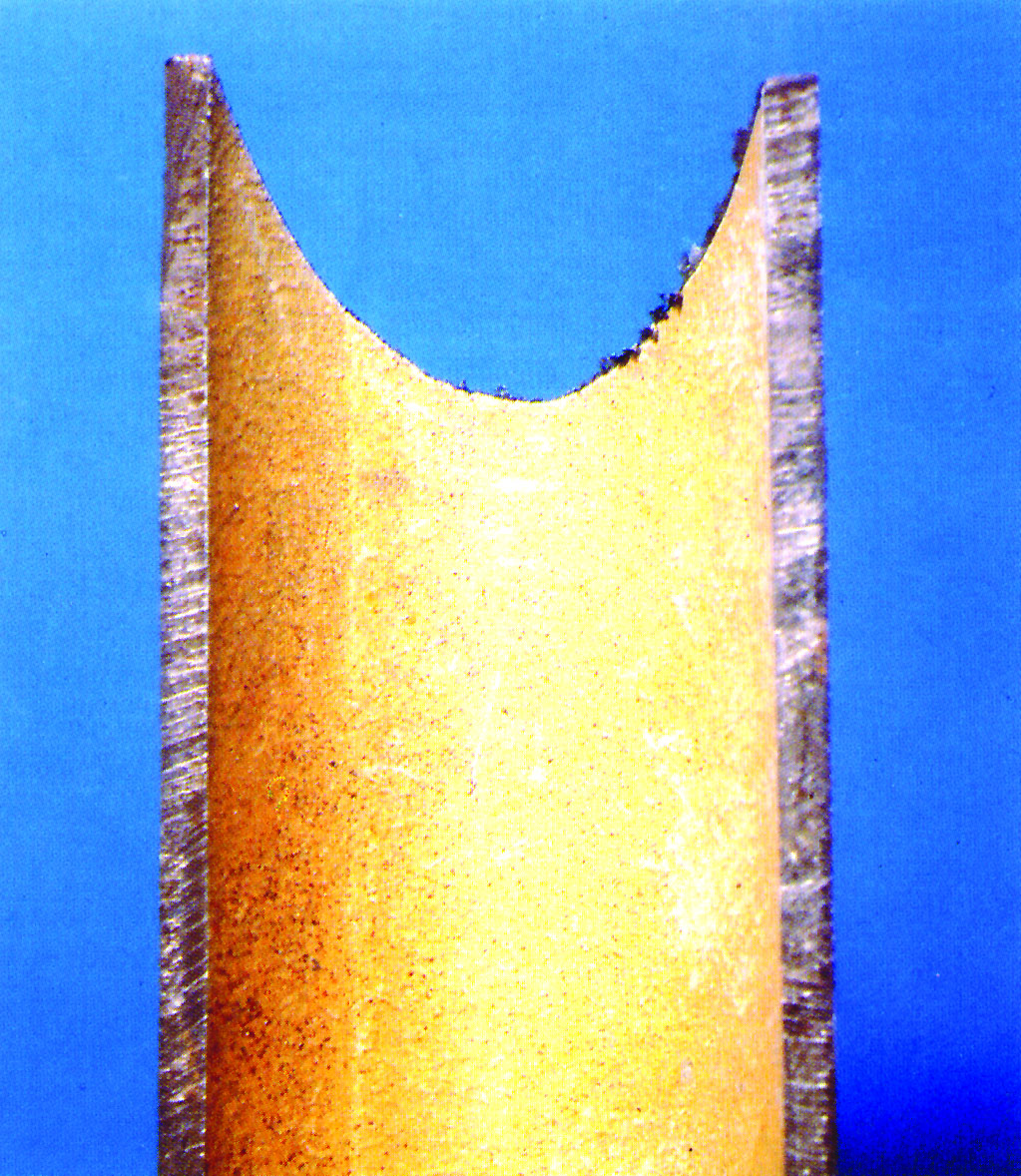

| This is what your pipes and heating devices look like without using of special tools | The pipe where the water is treated with Siliphos® | |

|

|

|

| Rusty pipe | Scaled pipe | |

Advantages of Siliphos®:

- protects industrial water systems, utilities, hotels, public buildings, cottages from scale and corrosion;

- prevents the formation of so-called "brown water";

- reduces the cost of repair/replacement of water systems equipment and extends their service life;

- saves energy;

- does not require electrical installation;

- easy to do maintenance.

Siliphos® is a cost-effective way to protect water systems from scale and corrosion

Corrosion prevention using Siliphos®

Due to the precise concentration of polyphosphates, Siliphos® prevents the formation of scale, deposits and corrosion. The phosphates contained in Siliphos® are a well-balanced blend of dietary organic phosphates, which are approved for drinking water treatment. Phosphates slow down the cathode and corrosion processes, creating a synergistic effect.

Thanks to the successful combination of the corrosion-absorbing properties of the phosphates and silicates included in this product, the thinnest protective film is created on the metal surface, reliably protecting it from corrosion. It is very important that a very low concentration of Siliphos® (2-3 mg/l) is sufficient for reliable protection against corrosion and scale formation.

Deceleration and descaling of scale

Siliphos® slowly dissolves and removes metal deposits previously formed in the pipes. It cannot be said that Siliphos® does not destroy scale in the full sense of the word. This reagent protects against the formation of new iron oxide/hydroxide deposits and softens accumulated deposits, which are gradually washed away by water.

The time required to remove deposits depends on a large number of factors, including the number and composition of deposits. The process can take from 4 days to 6 months and longer. Typical brown scale (iron oxide, hydroxide) can be either completely removed or partially removed. However, it is very difficult to remove white deposits of calcium carbonate or silicates. In most cases, it is only possible to stop their further formation.

Defective surfaces of the walls of old pipelines are covered with soft iron oxide deposits. The water treated with Siliphos® makes these deposits hard, thus preventing the defects (holes, small cracks) from increasing in size. This is a unique feature of several types of phosphates in Siliphos®.

Preventing the formation of "brown water"

The brown colour of the water can be prevented by using Siliphos®. This effect is important in the initial stage of water treatment, when the water contains a certain amount of Fe3+. Siliphos® is absorbed by iron oxide/hydroxide particles, thus protecting against the agglomeration of these particles and darkening of the water.

Siliphos® dispensers

Siliphos® dispensers can be used in any water system. They do not require any power supply and are easy to install. In the dispensers Siliphos® granules are recommended to be refilled every 3-6 months. The procedure for changing granules is very simple.

Siliphos® hot water treatment

Siliphos® system

|

|

- Siliphos® granules.

- Siliphos® dispensers. The dispensers are installed in the water system and filled with Siliphos® granules. Flowing tap water passes through the dispenser and dissolves the installed small amount of Siliphos®. Water pressure surges do not affect the operation of the dispenser.

Siliphos® dispensers are made of sturdy plastic and the container is made of fiberglass reinforced plastic. Possible volume of the reagent container is from 0.5 kg to 5 kg. The larger dispensers (200 kg) are made of welded steel. The volume of the dispenser depends on the volume of water consumption.

Dispenser's characteristics

|

Size |

Water consumption, m3/hour |

Dispenser volume, kg |

Materials |

|

1a |

less than 0,1 |

0,5 |

Transparent plastic |

|

1b |

0,1-0,3 |

1 |

|

|

2 |

0,2-0,3 |

2 |

|

|

3 |

0,3-0,4 |

3 |

|

|

4 |

0,5-0,6 |

4 |

|

|

5 |

0,8-2,0 |

10 |

Welded steel, observation window, lacquered finish |

|

6 |

2,0-3,0 |

20 |

|

|

7 |

3,0-4,0 |

30 |

|

|

8 |

4,0-7,0 |

50 |

|

|

9 |

7,0-10,0 |

80 |

|

|

10 |

10,0-13,0 |

100 |

|

|

11 |

13,0-18,0 |

150 |

|

|

12 |

18,0-30,0 |

200 |