Ultraviolet irradiation in water treatment is used to remove bacteria and viruses. The lamp installed in the equipment treats water with UV irradiation, thus purifying it from existing microorganisms. The UV equipment can be either a stand-alone device or one of the levels of the drinking water treatment system.

UV disinfection filters are used in a wide range of applications: in the food and cosmetics industries, urban water treatment systems, reverse osmosis systems, air conditioning systems, to prevent Legionella in hot water supply systems and swimming pools, in fisheries, to produce clean water for laboratory research, water for reclamation in horticulture and food industry.

Water passing through the UV disinfection filter housing is treated with UV lamps. The UV lamp light (90%), concentrated on a 254nm long luminescent spectrum, removes microorganisms (water and airborne bacteria, viruses, yeasts and mold). The light rays of UV-C pass through the cells of the microorganisms' walls, destroying them and preventing their reappearance.

UV disinfection filter consists of: stainless steel UV lamp housing, UV lamp, power supply unit. The main component of all UV filters is the UV lamp.

Advantages of the Ultraaqua Ultratherm Longlife lamp:

- Strong;

- Economical;

- Powerful;

- Has a long service life (16000 hours);

- High quality;

- Has an optimized wide range of temperatures (from 500C to 4000C).

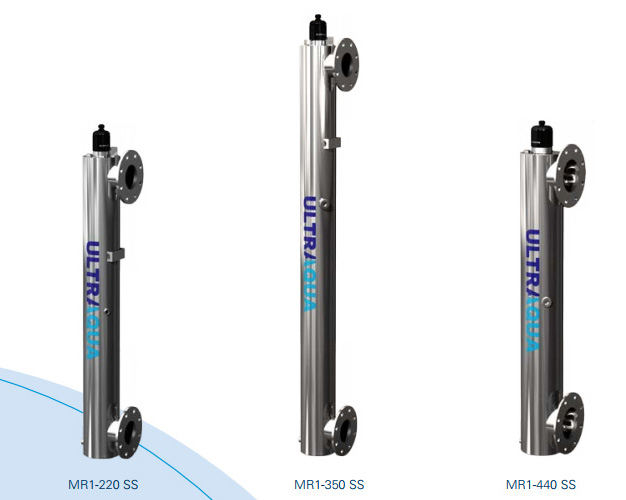

Three standard series 220 SS, 350 SS (U-configuration) and 440 SS (InLine configuration) cover a wide range of water system performance

In order to match an existing water supply system, a UV configuration is often used when the input (connection) and output are at the same level (InLine configuration). If a UV system is mounted with a bypass, the best solution is a U-configuration.

SS series for general water disinfection (U-configuration)

The SS series (U-configuration) is used if the UV system is mounted using bypass.

The ULTRAAQUA SS series filters are made of AISI 316L stainless steel and are suitable for virtually any water disinfection.

The main advantages of Ultraqua UV filters for water disinfection:

- Corrosion-resistant construction from stainless steel AISI 316L;

- Easy installation, operation and maintenance;

- Better efficiency thanks to integrated UV reflector;

- Operating pressure up to 10 bar;

- No additional tools are required for regular maintenance;

- Can be used with standard or optional controllers.

Technical data: 220 SS series

|

220 SS series |

MR1-220SS |

MR3-220SS |

MR4-220SS |

MR6-220SS |

MR8-220SS |

MR12-220SS |

MR16-220SS |

Productivity, m3/hour |

38 |

110 |

150 |

225 |

340 |

490 |

620 |

Lamp power, kW |

0.25 |

0.75 |

1.0 |

1.5 |

2.0 |

3.0 |

4.0 |

Connection diameter |

DN80 |

DN125 |

DN150 |

DN200 |

DN200 |

DN250 |

DN250 |

Technical data: 350 SS series

|

350SS series |

MR1-350SS |

MR3-350SS |

MR4-350SS |

MR6-350SS |

MR8-350SS |

MR12-350SS |

MR16-350SS |

Productivity, m3/hour |

60 |

260 |

390 |

600 |

870 |

1300 |

1650 |

Lamp power, kW |

0.4 |

1.1 |

1.5 |

2.3 |

3.0 |

4.5 |

6.0 |

Connection diameter |

DN100 |

DN150 |

DN150 |

DN200 |

DN250 |

DN300 |

DN300 |

440 SS series (InLine series)

The 440 SS series with InLine configuration is used when the input (connection) and output would be at the same level.

Technical data: 440 SS series

|

440 SS series |

MR1-440SS |

MR4-440SS |

MR6-440SS |

MR10-440SS |

MR14-440SS |

Productivity, m3/hour |

68 |

230 |

420 |

690 |

990 |

Lamp power, kW |

0.5 |

1.9 |

2.8 |

4.7 |

6.6 |

Connection diameter |

DN100 |

DN200 |

DN300 |

DN300 |

DN400 |

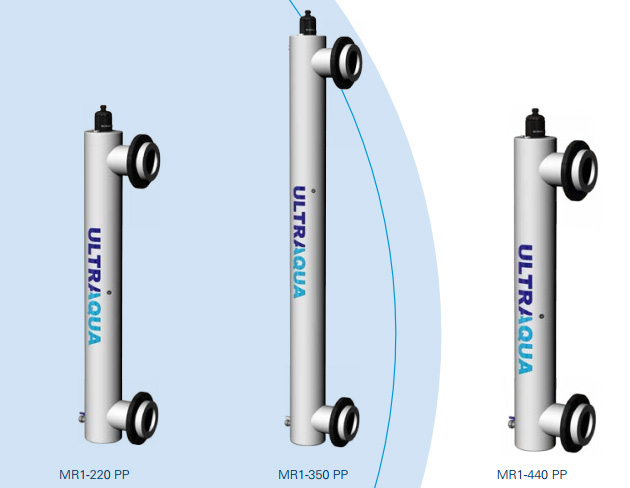

Non-corrosive PP series

ULTRAAQUA PP series is made of polypropylene. The filters of this series are very versatile, as they have an interval of resistance to corrosion from 5 to 1650 m3/hour. As a result, the optimal ratio of price and quality. A large number of customers choose the PP series for cleaning their corrosive liquids.

Advantages:

- ULTRAAQUA filters of PP series - high quality and reasonable prices;

- They are universal as they have an interval of corrosion resistance from 5 to 1650 m3/h;

- Can be used with standard or optional controllers;

- Anticorrosive design, temperature sensor in titanium case;

- Easy installation, use and maintenance;

- Can be used with standards/non-standard control systems;

- UV monitoring is available thanks to UV ÖNORM digital certified sensors;

- No additional tools are required for regular maintenance;

- DIN or ANSI connection possible;

- Guaranteed operating time of the lamp is 16000 hours.

The main advantages (PP) in compared to polyvinylchloride (PVC) and high-density polyethylene (PEHD):

- PP is more temperature-resistant

- PP is more resistant to pressure

- PP is resistant to salts, acids, alkalis, oil, etc.

- PP has a long service life

Technical data: 220 PP series

|

220 PP series |

MR1-220PP |

MR3-220PP |

MR4-220PP |

MR6-220PP |

MR8-220PP |

MR12-220PP |

MR16-220PP |

Productivity, m3/hour |

35 |

115 |

155 |

230 |

310 |

460 |

590 |

Lamp power, kW |

0.20 |

0.70 |

1.0 |

1.4 |

1.9 |

2.9 |

3.8 |

Connection diameter |

DN80 |

DN150 |

DN150 |

DN200 |

DN200 |

DN250 |

DN250 |

Technical data: 350 PP series

|

350 PP series |

MR1-350PP |

MR3-350PP |

MR4-350PP |

MR6-350PP |

MR8-350PP |

MR12-350PP |

MR16-350PP |

Productivity, m3/hour |

55 |

245 |

365 |

570 |

830 |

1250 |

1650 |

Lamp power, kW |

0.4 |

1.1 |

1.5 |

2.3 |

3.0 |

4.95 |

6.0 |

Connection diameter |

DN100 |

DN150 |

DN150 |

DN200 |

DN250 |

DN300 |

DN300 |

According to your needs, ŠOMIS also offers optimized UV filter systems (e.g. with specific connection and location diameters or non-standard solutions).